All subsidiaries of

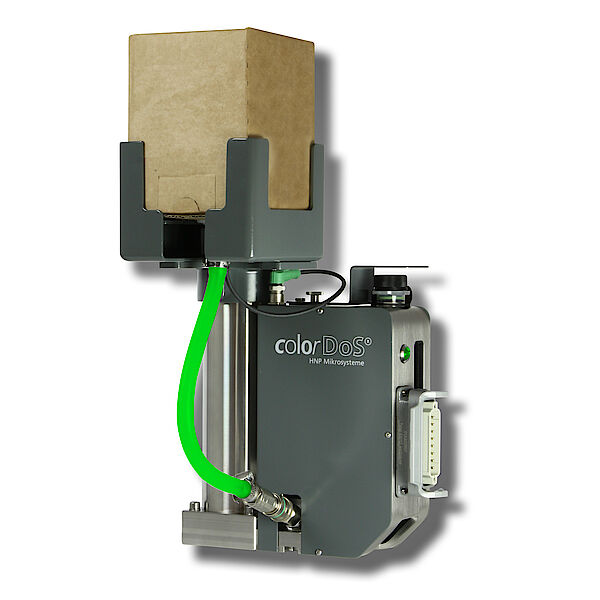

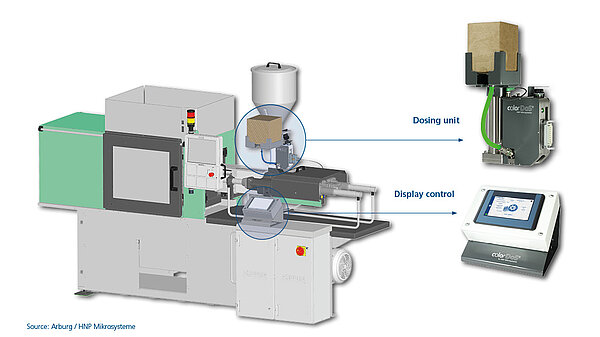

- Compact dosing system: Easy installation directly above the feed area of the injection molding machine

- Gentle precision dosing: High color fidelity with minimum color addition thanks to micro annular gear pump (0.02 to 100 ml color per shot)

- Clean handling due to drip-free quick-connect couplings, short fluid connections, dosing nozzle design for smallest color quantities without color carryover in the feed area

- Fast color change: Low empty volume enables fast rinsing of the pump module and thus a fast color change

- Functions of the colorDoS control system

- Different operator levels: Operator, administrator, service

- Remaining run time display with adjustable advance warning time until container changeover

- Color code management: storage of up to 30 color code recipes

- Cleaning mode enables fast color change

- Alarm manager displays warnings (e.g. fill level low) or malfunctions and can stop the injection molding machine to avoid scrap

- As color packaging we recommend our returnable container COLOR CUBE

- Related Links:

- Information and contact to the manufacturer (HNP Mikrosysteme)

- Explanatory video (Youtube)

- Live-Presentation at FAKUMA 2021 (Youtube)